BEWG has thoroughly embedded low-carbon management into its entire business framework. By taking effective measures in low-carbon operation, low-carbon technologies, low-carbon construction, low-carbon offices, and low-carbon collaboration, BEWG actively advances energy conservation and consumption reduction, steadfastly fulfilling its corporate mission of green and low-carbon development.

In 2024, three of the Group’s water plants were honoured as the "Green and Low-Carbon Benchmark Wastewater Treatment Plants" by national ministries and commissions. Looking ahead, we will continue to increase investment in R&D, driving the adoption and promotion of advanced low-carbon technologies and products throughout the water industry. Through these efforts, we aim to establish more green and low-carbon benchmark water plants.

Low-Carbon Operation

The Group adopts the lean energy management model to meticulously manage the energy consumption in its production and operations, thereby maximising energy efficiency across all processes. We set energy consumption control targets for the current year based on the actual energy consumption of the previous year, and conduct monthly tracking during operations. For any abnormal energy consumption data detected, we will collaborate with relevant personnel to analyse the root causes. Based on expert recommendations, we will implement corrective measures to further improving energy efficiency. The Group has established a system and equipment evaluation model. We evaluate equipment energy efficiency according to relevant standards, and identify energy-inefficient equipment. Energy-efficient equipment operation has been achieved through multiple paths, such as optimising equipment operation methods, precisely controlling processes, selecting high-efficiency equipment, and adjusting the power supply frequency of motors. In addition, we continue energy-saving upgrading of energy-intensive equipment like submersible centrifugal pumps, submersible mixers, and aeration blowers. By the end of 2024, a total of RMB 20.67 million had been invested in technological renovation projects for energy conservation, with an annual electricity savings of RMB 9.41 million and an annual reduction of 14,930 MWh in electricity consumption.

BEWG is actively seeking opportunities to replace traditional energy sources with renewable energy and low-emission fuels. We make full use of the roofs of the water plants by installing distributed solar PV power generation devices to provide clean power for them. By the end of 2024, the Group had 50 water plants using solar PV power generation.

We continue to advance energy recovery technologies such as water source heat pumps and anaerobic digestion to enhance energy reuse. In sewage treatment projects, the water source heat pumps recycle the heat energy generated from sewage treatment to provide cooling and heating for office buildings, production areas and residential areas in the plants. In sludge treatment projects, we leverage biogas generated through anaerobic digestion to power our production processes. The biogas residue, after deep dehydration, is used as nutrient soil. This method achieves both the harmless treatment and resource utilisation of the sludge. Moreover, we actively engage in research on topics such as temperature changes along the sewage source heat pumps to advance the energy recovery technologies.

Low-Carbon Technologies

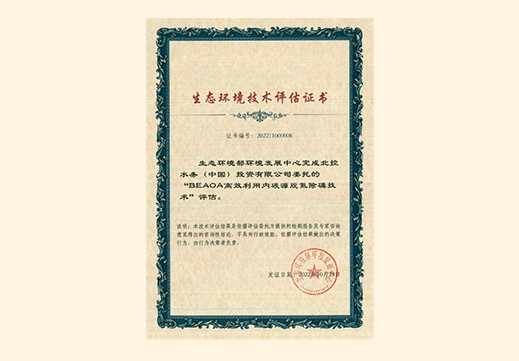

Over the years, leveraging its extensive experience in the field of sewage treatment, the Group has continuously increased investment in R&D of low-carbon processes and control technologies. As a result, we have successfully developed a series of new low-carbon technological products, significantly improved the efficiency of sewage treatment and effectively reducing energy consumption and operating costs.

Low-Carbon Construction

BEWG values low-carbon construction and makes continuous efforts in R&D to improve construction technology and project application, so as to reduce carbon emissions during construction. We have defined requirements on project energy consumption and material consumption during the construction phase in the Interim Administrative Measures for Engineering Products Appraisal of BEWG, guiding the optimisation of process design and equipment selection during the construction phase with low-carbon operation standards during the operation period.

Low-Carbon Collaboration

The Group has established the "X in Water" Expert Group to comprehensively integrate the resources of science and technology, think tanks and platforms. In March 2024, the "X in Water" (Shenzhen) Summit Forum was held at the Tsinghua Shenzhen International Graduate School, and was simultaneously live-streamed on multiple online platforms. With the theme of "Low Carbon and Water Resources", this forum conducted in-depth discussions on the challenges of water resource management and water security guarantee faced by the Guangdong-Hong Kong-Macao Greater Bay Area in the "dual carbon" era. Experts present also delivered keynote reports on topics such as water resource management, GHG emissions from sewage systems, challenges in urban water systems and a roadmap for carbon neutrality in urban sewage, with a cumulative attendance of over 40,000 person-times. In January 2025, we officially released the "X in Water" Development Report-New Strategy of Seawater Desalination and the "X in Water" Development Report-Urban Sewage Carbon Neutrality Roadmap. The former reported on the national water resource strategy matching the economic and social development goals in the new era, and the latter presented the world's first industry-level carbon neutrality roadmap proposed by a non-governmental organization, attracting the attention of more than one million people from different groups such as government departments, scientific research institutions and industry enterprises.

Low-Carbon Offices

In 2024, the Group updated daily office-related systems such as the Measures for Regulating the Use of Meeting Rooms and Video Conferences and the Notice on Further Strengthening the Standardized Management of Business Trips and systematically promoted the concept of low-carbon office from multiple dimensions including energy conservation, water saving and material saving.

The carbon intensity reduction targets are set for businesses in Chinese mainland

By 2030, the carbon emission per unit of revenue (tonnes of CO₂ equivalent / 10,000 RMB) will be reduced by 2% compared to 2023.

By 2030, the carbon emission per unit of treated water (tonnes of CO₂ equivalent / 10,000 tonnes water) will be reduced by 4% compared to 2023.

| Indicator | GHG Data in 2024 | Unit |

| Water business in Chinese mainland | ||

| GHG emissions – Scope 1 | 5,147 | tCO2e |

| GHG emissions – Scope 2 | 1,009,615 | tCO2e |

| Total GHG emissions | 1,014,762 | tCO2e |

| Overseas water business | ||

| GHG emissions – Scope 1 | 2,183 | tCO2e |

| GHG emissions – Scope 2 | 90,991 | tCO2e |

| Total GHG emissions | 93,175 | tCO2e |

| Solid waste business | ||

| GHG emissions – Scope 1 | 4,883 | tCO2e |

| GHG emissions – Scope 2 | 9,390 | tCO2e |

| Total GHG emissions | 14,273 | tCO2e |

| Office building | ||

| GHG emissions – Scope 1 | 1,587 | tCO2e |

| GHG emissions – Scope 2 | 2,710 | tCO2e |

| Total GHG emissions | 4,297 | tCO2e |

| Total | ||

| Total GHG emissions | 1,126,506 | tCO2e |

| Total GHG emissions intensity | 0.46 | tCO2e/10,000 RMB |