Low carbon and friendly reduction and circulation | Please check the sludge treatment and disposal solution of BEWG 2021-07-19

Difficulties in the balance of water and sludge, sludge disposal and resource transformation are difficult in the field of water treatment and even the environment, and they are also one of the focus issues concerned by relevant departments. In June this year, the National Development and Reform Commission and the Ministry of Housing and Urban-Rural Development issued “14th Five Year Urban Sewage Treatment and Resource Utilization Development Plan”, which proposed to pay equal attention to sludge and water, accelerate to make up for the shortcomings of sludge disposal facilities, solve the difficulties of sludge disposal, to achieve harmlessness and promote resource utilization.

The concept of "determining the thoughts by way and determining the treatment by disposal" leads the development of sludge treatment and disposal industry.

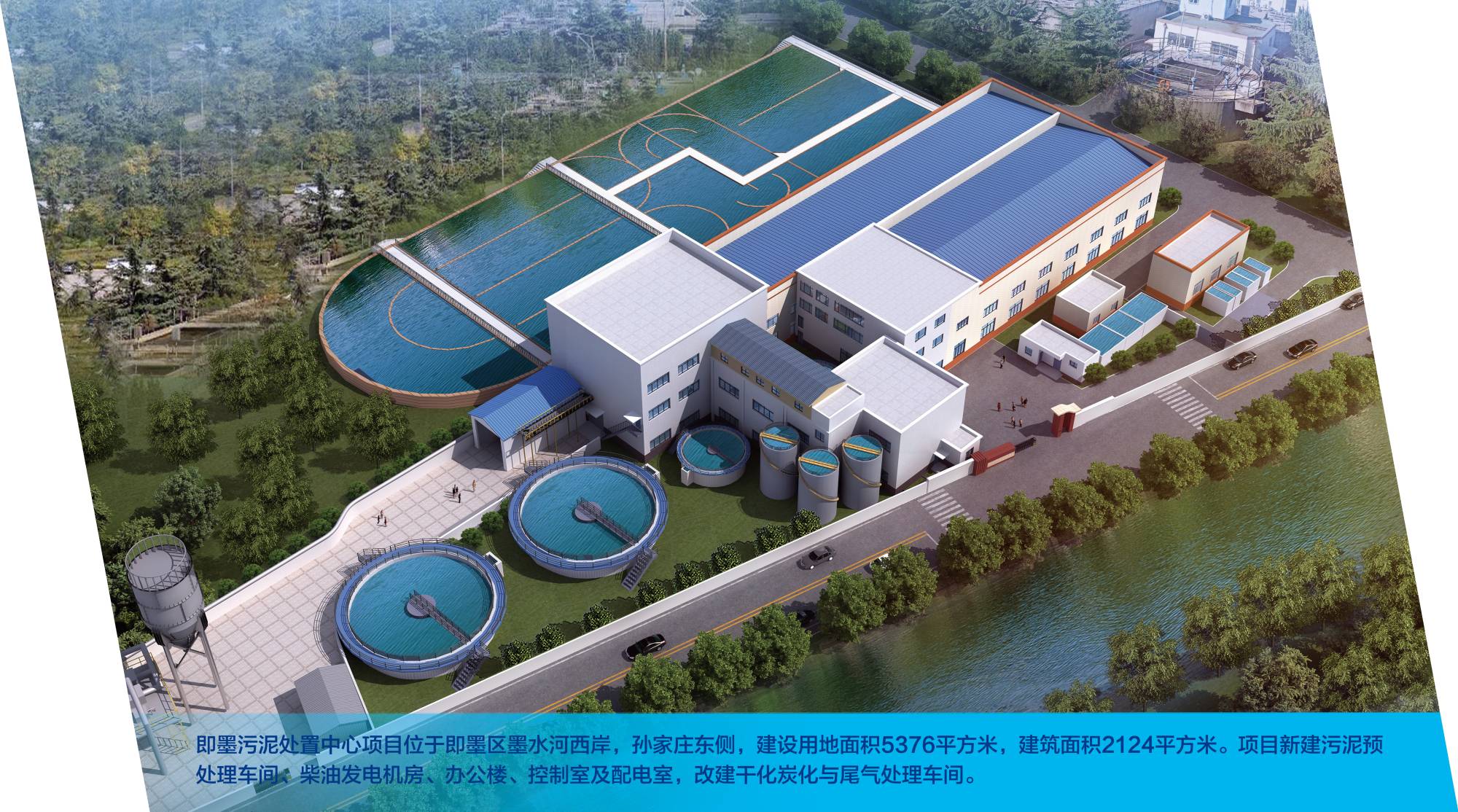

Over the years, BEWG has continuously learned from its experience and systematically summarized, forming a system guarantee system for the whole value chain of sludge, providing customers with a series of municipal sludge treatment and disposal system solutions including "regional sludge outlet diagnosis", "optimal disposal path mining", "technical route integration and optimization", "full life cycle consulting and operation management services". At the same time, the Qingdao Jimo sludge treatment and disposal center project is one of the typical cases through the in-depth excavation and establishment of the linkage between the city's existing industrial resources and the sludge treatment and disposal industry, and the reconstruction of a complete resource reuse circular economy industry chain.

"The largest single sludge carbonization project in China" - Qingdao Jimo sludge treatment and disposal center

Jimo District of Qingdao is a national environmental protection model city, an excellent tourist city in China, and a provincial civilized city. Its comprehensive competitiveness ranks among the top ten in the country. With the rapid development of Jimo district and the continuous improvement of infrastructure construction, sludge treatment and disposal problems have become increasingly prominent, such as the increasing amount of sludge disposal, the lack of environmentally friendly landfill facilities, the inability to achieve harmless reuse, and environmental and social problems caused by bad odor of sludge.

Jimo District government attaches great importance to sludge treatment and disposal, carries out special study, decides to establish a centralized sludge disposal center, and collects technical solutions nationwide. After several rounds of expert argumentation and technical route selection, and comprehensive consideration of various factors such as land use, reduction, harmlessness, atmospheric impact, social stability, final decision was made to adopt the carbonization process for in-situ sludge treatment. With many years of professional experience and innovative solutions, BEWG has been recognized by customers in Qingdao Jimo sludge treatment and disposal center project.

Systematic planning, research carbon residue outlets

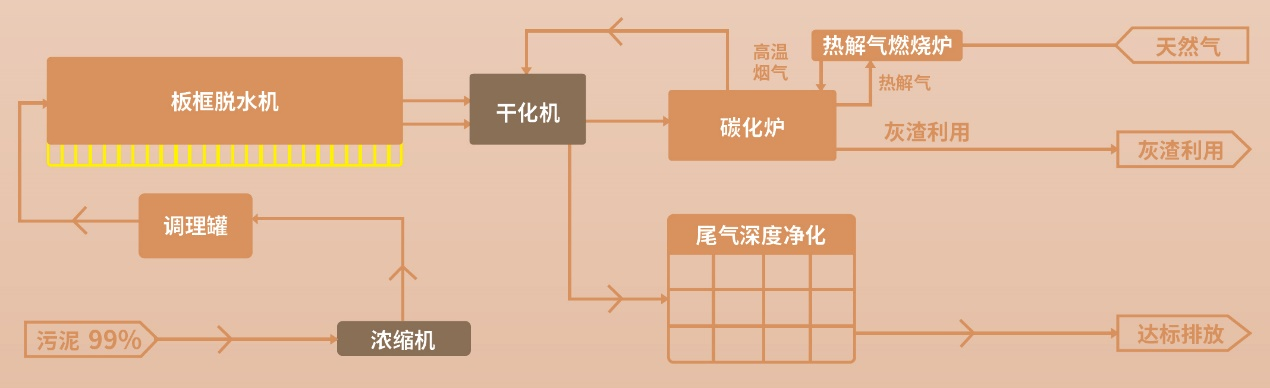

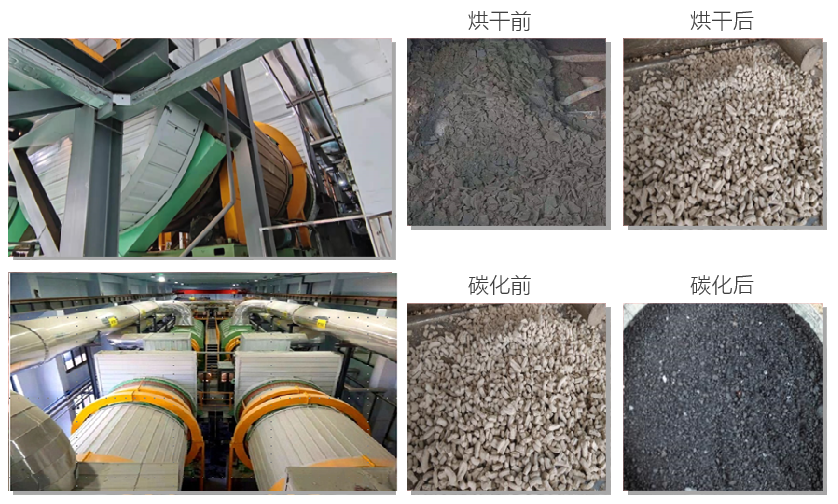

Through the overall analysis and systematic planning from the sludge producing end to the outlet end, taking the carbon slag outlet research as the starting point and as one of the important basis for judging whether the process is feasible, the sludge carbonization process route of "deep dehydration + drying + carbonization + flue gas purification + building materials utilization" with a treatment scale of 300t/d (80% water content) is developed.

Mud and water synergy to release urban environmental capacity

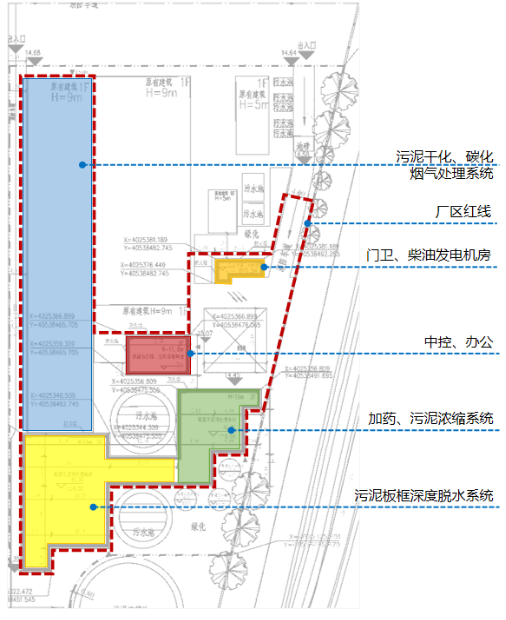

In order to avoid secondary pollution during transportation, the project adopts in-situ treatment of sludge produced by sewage treatment plant. However, the site space condition is very limited, among which the construction area of the main drying and carbonization treatment is only 1500㎡, less than one third of the normal design level. In this regard, we should give full play to our own technological advantages of "sludge water synergy", and through the transformation of the original sludge dewatering machine room of the sewage plant, divide the sludge disposal into multiple modules and distribute in the original structures of the sewage plant. While completing the sludge treatment and disposal efficiently, we should make compact and intensive use of land and release the urban environmental capacity.

Independent research and development, providing complete sludge carbonization solutions

In order to achieve the optimal disposal path, research on sludge characteristics, carbonization process design, process energy balance, drying and carbonization equipment and carbon residue resource utilization are carried out, And five core process systems including "sludge receiving and storage system", "sludge thickening and conditioning and deep dehydration system", "sludge drying system", "sludge pyrolysis and carbonization system" and "flue gas treatment system" have been formed, And the complete sludge carbonization process technology of the three auxiliary systems of "carbon residue cooling and storage system", "compressed air and nitrogen system" and "industrial circulating cooling water system", which can meet the national standards for sludge disposal.

Through the integration of five core process systems + three auxiliary systems, the carbonation technology independently developed by BEWG has five characteristics:

Advanced process and stable operation: medium and high temperature pyrolysis and carbonization process is adopted, no tar is produced during pyrolysis, the pyrolysis gas combustion temperature is greater than 850℃, the pollutants are decomposed thoroughly to help the system run stably and reliably.

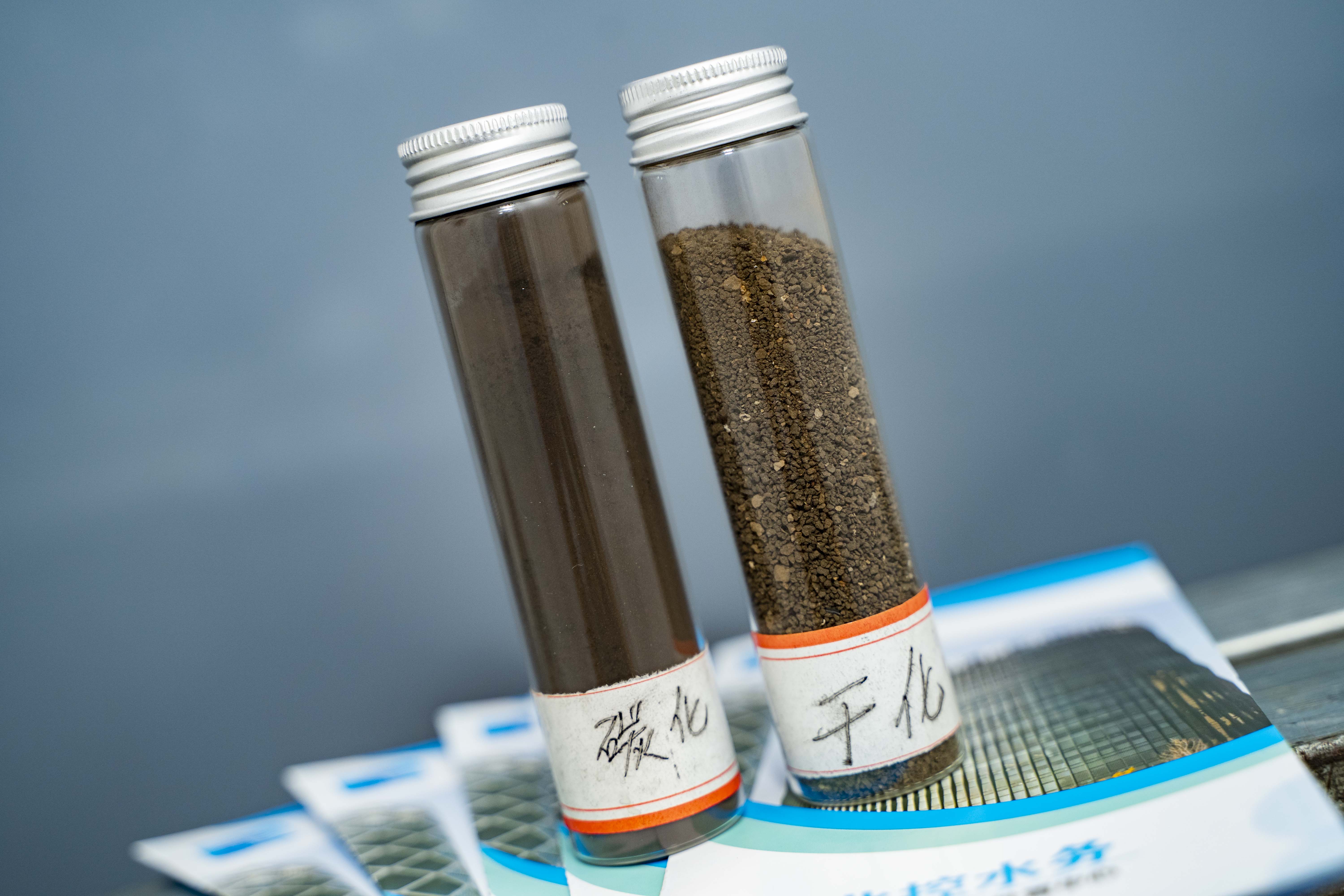

Few end products and wide utilization range: the sludge reduction is more than 85%, the moisture content of the end products is ≤ 1%, the heavy metals in the sludge are solidified, and the nutrients such as nitrogen, phosphorus and potassium are retained in the sludge carbon, meeting the requirements of land use and building materials utilization, and is conducive to the sludge resource utilization.

Green and low-carbon, energy self-circulation: the combustible gas generated in the carbonization pyrolysis process is recycled to reduce energy consumption. Part of the organic carbon is sealed in the carbon residue, reducing greenhouse gas emissions, and helping to promote the realization of the "double carbon" goal.

Small flue gas volume and high emission standard: the flue gas emission meets the national pollution control standard of domestic waste incineration (GB18485-2014) and the local standard of Shandong Province, and the emission is only equivalent to about 30-40% of sludge incineration.

No dioxin and environment-friendly: no oxygen in the pyrolysis process, which eliminates the conditions for dioxin production from the source. The sludge in the workshop is fully enclosed, and the sludge odor is cleaned by cooperative combustion, effectively avoiding pollution and becoming an environment-friendly sludge treatment and disposal project.

Stable running, becoming the leading process of sludge carbonization treatment in China

Since the project has been running for two years, the sludge treatment capacity has exceeded 220 tons/day, with reasonable operation cost, stable output, and friendly production environment, realizing the sludge reduction, harmlessness, stabilization, and resourceization. Through continuous improvement of management, it has become the project with the largest actual treatment scale, the longest continuous operation time and the lowest direct operation cost in the domestic sludge carbonization treatment process, and fully achieving the expected goal.

Three core competitiveness of BEWG effectively solve sludge treatment and disposal problems

Systematization of solutions: while reshaping the complete resource reuse circular economy industry chain, BEWG gives full play to its product strengths in the field of environmental protection, and through systematization of solutions", plan as a whole from the sludge production end to the outlet en, provides customers with systematic solutions of "determining the thoughts by way and determining the treatment by disposal".

Engineering Modularization: divide product function modularization by output, realize module integration, combination and development according to the final consumption path, and provide customers with modular optimal configuration and integration.

Service specialization: we have a whole chain of professional team services from consulting, planning, solution, engineering construction to operation management, and realizes customized professional technical support for customers with proprietary technology.

Under the carbon peaking and carbon neutrality goals, the environmental protection industry will usher in a new round of important window period. Combined with the "30·60" double carbon goal, BEWG will further deepen the application exploration of sludge disposal in many fields such as resourceization in building materials, water quality purification, river ecological restoration, and actively explore more safe, efficient, and environment-friendly diversified sludge treatment and disposal paths, contribute to the modernization of harmonious coexistence between man and nature.