Today, the intelligent robot independently researched and developed by BEWG made its debut to the public 2021-08-20

On August 20, process technology productization seminar salon in sewage treatment industry and the first “Double-Hundred Leap” sewage treatment benchmark construction technology product pre-review held by the “Double-Hundred Leap” Sewage Treatment Benchmarking Alliance (hereinafter referred to as “Double-Hundred Alliance”) were held in Beijing. The meeting was held in an offline + video mode. Hang Shijun, Chief Consulting Engineer of the Group, attended the meeting as an industry guest, and Liu Weiyan, Vice President of the Group, attended the meeting as an enterprise representative.

At this pre-review meeting, Hang Shijun said that the technology maturity of the industry was perfected, and the productization of technology was ready, so it needed to be put on the agenda and accelerated the promotion. Through the support from intelligent means to the original technology, more innovative “specialized, refined, special and new” technologies could be produced, which could better serve the sewage treatment projects, so as to better help reduce carbon and increase efficiency.

During the discussion, Liu Weiyan stressed that with the continuous development of the environmental industry, the sewage operation business has gradually encountered the bottleneck of industry level improvement. Through the widespread adoption of smart water in sewage treatment plants, which could effectively improve the quality and efficiency, and promote the high-quality development of the sewage industry in the context of “Double Carbon”. She said that BEWG has been committed to the systematic research on the fine and intelligence of sewage treatment, gradually ground out a series of mature intelligent application process packages, and achieved good quality and high efficiency in practice, next, the Group would continue to expand the application scenario and scope of use and continue to build excellent operation capacity.

Wei bin, Department Manager of the Sewage Management Department of the Group’s Operation and Management Center, made a technical product presentation and answered questions. He introduced in detail the three hardcore technology products of biochemical system intelligent control technology (BE-EMR), requiredly controlled aeration process package (BE-CMR) and advanced oxidation process package (BE-Fenton), which have been put into production and operation by BEWG.

Let's unveil their mysteries:

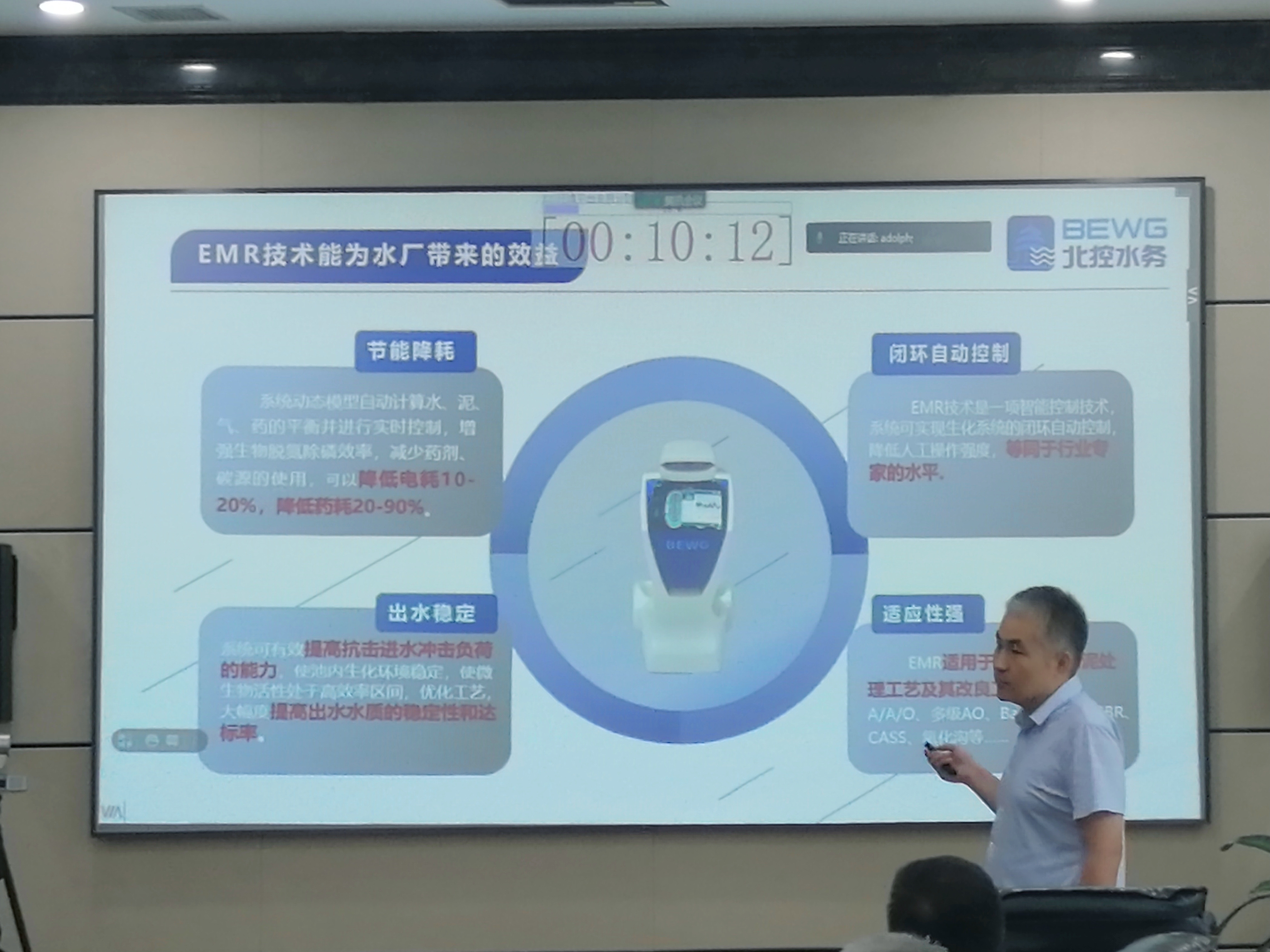

Biochemical system intelligent control technology (BE-EMR)

A system-wide intelligent control technology for biochemical treatment, with the help of the technological intelligent robot “BEWG Xiaolan”, unattended and closed-loop control of the biochemical system operation can be realized. Through the intelligent control of various key process parameters such as water, mud, gas and chemical to reach the control level of industry operation experts, greatly save the power and chemical consumption of operation, reduce the power consumption by 10-20%, reduce the chemical consumption by 20-90%, and improve the water quality of treatment, improve the impact resistance of the system, and the control accuracy of dissolved oxygen reaches±0.1mg/L, reaching the industry-leading level.

Requiredly controlled aeration process package (BE-CMR)

A new type of sewage treatment process, with its unique reactor, equipment structure and intelligent control system, realizes advanced control results such as denitrifying phosphorus removal, simultaneous nitrification and denitrification, short-cut nitrification and denitrification, and endogenous respiration inhibition; When the carbon-nitrogen ratio (BOD5/TN) is lower than 1.7, the effluent TN is less than 8mg/L, the biological phosphorus removal rate is above 95%, and the effluent TN is below 5mg/L under normal carbon-nitrogen ratio condition.

Advanced oxidation process package (BE-Fenton)

A new Fenton advanced oxidation process package can achieve low-cost removal of refractory COD, effluent COD reaches below 20mg/L, and when the net COD removal amount is 30-40mg/L, the direct operating cost is as low as 0.36 yuan/ton , which is more than 50% lower than the traditional Fenton method and more than 60% lower than the ozone catalytic oxidation, and has the advantages of small footprint and low investment.

In the report, the participants expressed strong interest in the three products of BEWG. Shi Hanchang, a professor at the School of Environment, Tsinghua University, Wang Kaijun, a professor at the School of Environment, Tsinghua University, Yang Xiangping, the former General Manager of Beijing Urban Drainage Group, and Wang Hongchen, Assistant Dean at School of Environment and Natural Resources Renmin University of China, and other experts and representatives of participating enterprises had an in-depth exchanges on the principles, practical effects, advanced nature and universality of the technical products, and fully affirmed the low-cost and high-efficiency of the two process packages. The technological intelligent robot “BEWG Xiaolan” created by the Group attracted the attention and praise of on-site experts.

At the review site, a technical product evaluation committee composed of industry experts, alliance consultant experts, benchmarking experts, and specially-invited evaluation specialists selected the shortlisted technical products, and finally assessed whether the technical products are included in the manual. In the follow-up, the Secretariat of the Double-Hundred Alliance will announce the selection results, and recommend the results to the industry in various ways to better promote the sound development of the industry.

BEWG has always been committed to scientific and technological research and development and the promotion of major technology. With the wide application of a number of excellent products in the industry, it will effectively promote the the industry from extensive management to refined management and from low-level to high-level development, effectively promote the high-quality development of the sewage industry and comprehensively help achieve “Double Carbon” goal to achieve.

More

-

“Green pearl” decorates the beautiful countryside --BEWG rural sewage constructed wetland practice

-

Good news! BEWG won the bid for Beijing Haidian Daoxianghu Lake Reclaimed Water Plant Phase II Project

-

The green transfer station of reclaimed water circulation in BEWG area--River and lake water purification wetland