BEWG has attached great importance to the cultivation of innovation capability, established a sound innovation mechanism, continued to explore new models of industry-university-research collaborative innovation, stimulated the consciousness of internal innovation, and established an internal innovation mechanism to effectively promote production innovation, technological innovation, and management innovation, and taken innovation as the first driving force for leading future development and an important path for business progress, serving the country and society.

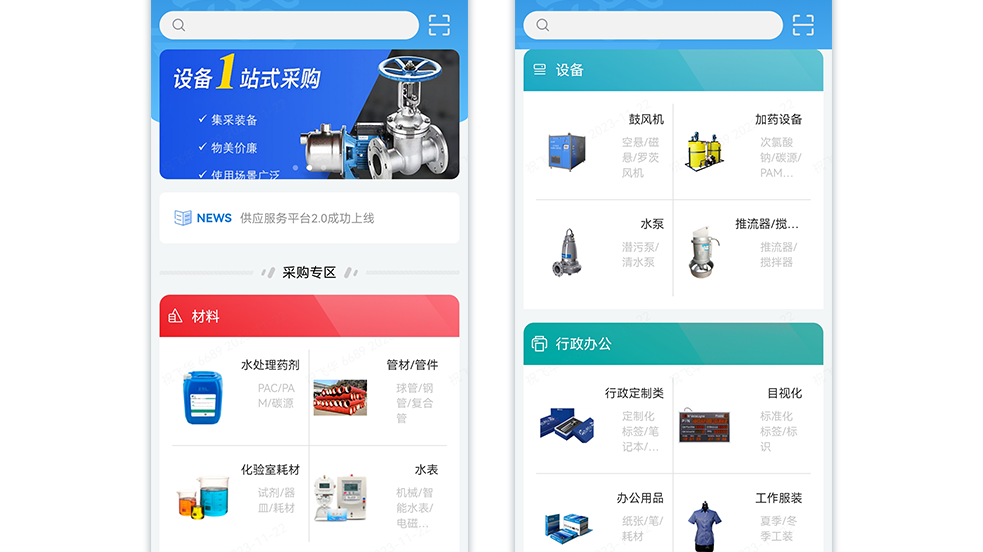

BEWG is seeking the obscure innovative practitioners who make contributions to operational excellence in ordinary positions, encourages more value generation, improves and expands the coverage, and focuses on the improvement of operation technology, equipment, process, operation method, working environment, etc. by employees in front-line positions to improve work efficiency, save costs, and raise quality.

BEWG escorts technological innovation by strengthening digital and information management, protecting intellectual property rights, establishing and standardizing the approval process and reward system for intellectual property application, standardizing independent project research of the Group, etc.

BEWG pays attention to the exploration of new management models, and expands new ways to improve and upgrade the management models, management mechanisms, investment and financing methods, etc. to empower the Group and achieve high-quality and rapid development of the Group.