BEAOA and BEWG speedgrain: The first batch of technical products of BEWG are officially launched 2022-04-28

On the morning of April 27, BEWG held a technology conference themed “innovation and truth-seeking, breakthrough and leadership” in Beijing, and publicly released two technical products BEAOA and BEWG speedgrain for the first time. At the press conference, the Group’s scientific and technological innovation and development strategy was systematically elaborated, the innovative technological achievements of BEAOA and BEWG speedgrain were comprehensively displayed, and the unveiling ceremony was held .

The technical products of BEAOA and BEWG speedgrain are officially launched

During the “14th Five-Year Plan” period, China’s ecological civilization construction entered a critical period of taking carbon reduction as the key strategic direction, promoting the synergy of pollution reduction and carbon reduction, promoting the comprehensive green transformation of economic and social development, and realizing the improvement of ecological environment quality from quantitative change to qualitative change. China has been strengthening the dominant position of enterprise innovation, continuously promoting key core technology research, and deepening the combination of industry-university-research-application. As the last barrier for pollutants to enter the water ecological environment, sewage treatment is of great significance to realize the virtuous cycle of the ecosystem.

As a flagship enterprise focusing on the recycling of water resources and the protection of water ecological environment, BEWG actively responds to the challenges of high-standard and high-quality development, takes innovation as one of the important strategies for enterprise development, continues to promote technological innovation, and constantly explores the path of industry-university-research transformation. The BEAOA and BEWG speedgrain technology products released this time are the long-term practical achievements of BEWG’s innovation strategy.

Focusing on pollution reduction and carbon reduction, BEAOA has become a highlight of the transformation of low-carbon scientific and technological achievements

In recent years, with the theme of building a high-quality urban sewage treatment system, China has continuously promoted urban sewage treatment and resource utilization, with growing demand for efficient and low-consumption sewage treatment technology. BEAOA is a new treatment process for efficient and deep nitrogen and phosphorus removal jointly developed by BEWG and academician Peng Yongzhen of the Chinese Academy of Engineering. It has become a powerful tool for pollution and carbon reduction in the process of sewage treatment.

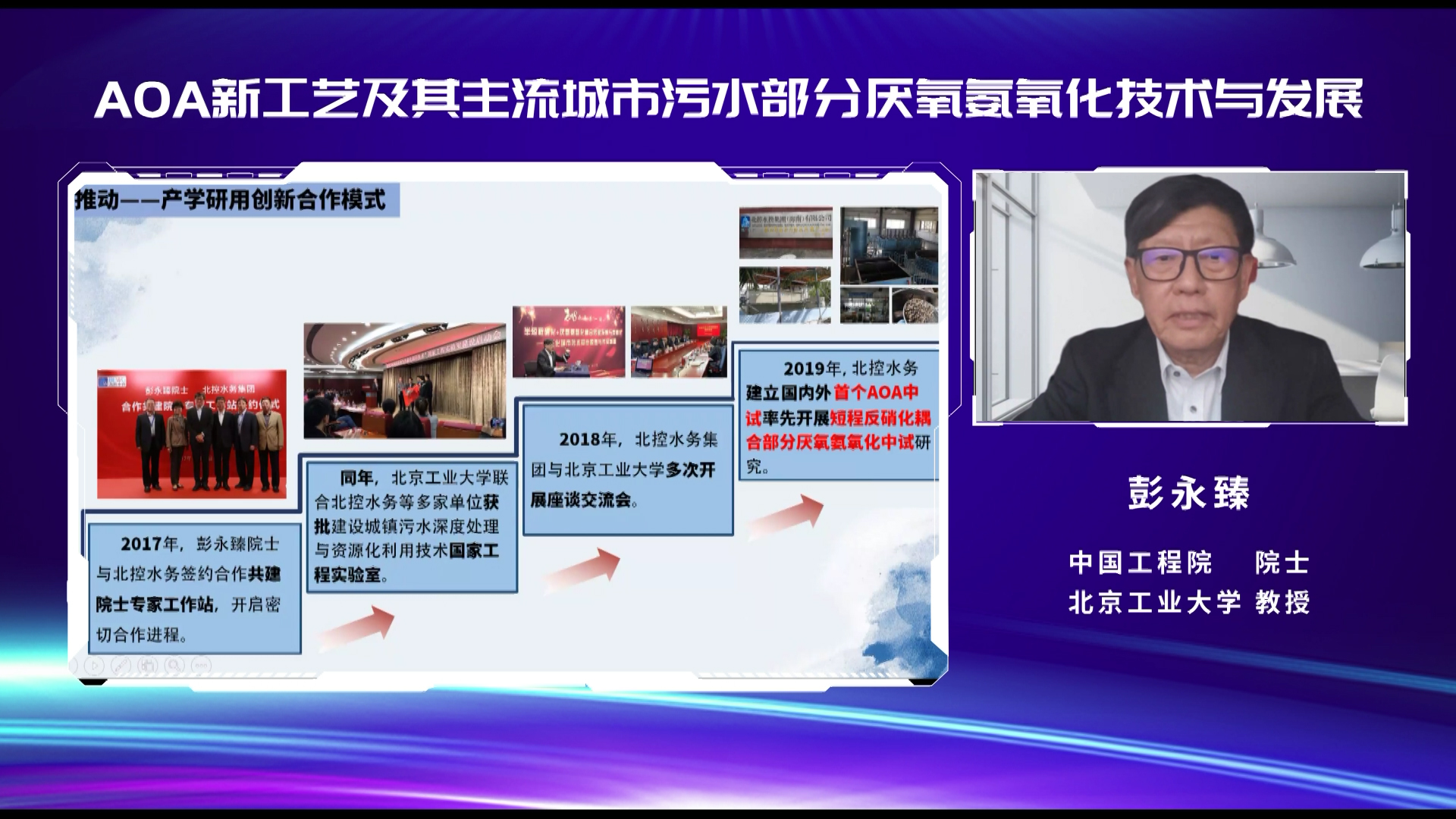

At the press conference, academician Peng Yongzhen made introductions by focusing on AOA new technology research & development and the results of technological transformation of coalition of college and enterprise. In order to solve the key bottleneck restricting the development of urban sewage treatment, academician Peng Yongzhen’s team took the lead in discovering the phenomenon of post endogenous denitrification since 2012, and first disclosed the sludge double reflux--AOA technology in 2018, making outstanding contributions to the field of international nitrogen and phosphorus removal technology. Meanwhile, academician Peng’s team actively explored the innovative cooperation mode of industry-university-research-application, promoted the transformation of scientific and technological achievements, and jointly carried out a number of new technology application tests with BEWG including AOA, short-range denitrification, anaerobic ammonia oxidation, etc. and the technical level is in a leading position at home and abroad.

BEWG started its technical layout in 2017, and set up a technical working group and a special scientific research project (independent project) in 2018 to quickly promote large-scale pilot plant test research. Based on the AOA technology concept proposed by academician Peng Yongzhen, BEWG and academician Peng carried out in-depth cooperation to integrate and jointly promote the basic research and engineering application, and took the lead in successfully carrying out the application practice of 100-ton pilot plant test and 10,000-ton in-situ transformation project at home and abroad, making the AOA technology complete the transformation from basic research to engineering application, and successfully created the technical products of BEAOA.

Xue Xiaofei, executive vice president of BEWG Research Institute, comprehensively interpreted the advantages, application scenarios and user values of the technical products of BEAOA. First, it has good effluent quality. The main water quality indicators of the total effluent can meet the national surface level Class III and Quasi Class IV standards. The total nitrogen removal efficiency is more than 85%, and it can withstand low temperature and low carbon nitrogen ratio sewage, so it is a high-quality process with high standards; second, it has energy conservation and consumption reduction. In the process of operation, aeration energy consumption can be saved by more than 25%, biological phosphorus removal efficiency can reach 90% (pilot plant test data), and the dosage of phosphorus removal agent can be significantly reduced (40%-100%), which can meet the requirements of low carbon nitrogen ratio water quality denitrification, realize zero carbon source dosing, save energy and material consumption while realizing in-situ sludge reduction of 30%, and systematically reduce carbon emissions of sewage treatment plants, so it is a high-quality choice for the sustainable development of the industry and even society; third, it has strong practicality. This technology is suitable for the in-situ transformation of water plants and is very easy to be coupled with various processes. With the features of land saving, convenience and wide application, it is easy to be promoted in the industry.

Currently, with the joint efforts of the technical R&D team, BEAOA technology process package and equipment products have been formed, which have been applied in many projects in Beijing, Shandong, Hainan, Guangxi, etc. In the future, it will also provide the design institutes, enterprises, governments and other customers with efficient, low-consumption, low-carbon and green sewage treatment innovative solutions and products.

Aiming at the characteristics of sewage quality in China, BEWG speedgrain innovates the biological treatment processBEWG speedgrain technology is a new technical product independently developed by BEWG based on aerobic granular sludge technology according to the characteristics of low carbon nitrogen ratio sewage quality in China. Zhang Lili, head of BEWG speedgrain R&D team, made a detailed introduction to the engineering research and transformation application of BEWG speedgrain technology.

Since the BEWG speedgrain technology research project was established in 2018, under the leadership and guidance of Zhang Lili, the 1000-ton production verification project was successfully completed, achieving continuous and stable operation records of more than 700 days, and the first domestic assembled products based on municipal sewage treatment with aerobic granular sludge technology were successfully created.

During this period, Zhang Lili’s team achieved breakthroughs in four core technologies, including “raw carbon distribution control technology”, “sludge rapid sedimentation control technology”, etc., successfully developed hardware equipment such as speedgrain distributor, speedgrain filter and speedgrain reaction intensifier, and built the control system of speedgrain database, speedgrain software system and speedgrain operation platform. The technical products of BEWG speedgrain have excellent sludge sedimentation performance, which can reduce energy consumption by more than 20% while realizing the high standard removal of sewage chemical oxygen demand, ammonia nitrogen, total nitrogen and total phosphorus, with land occupation of the project reduced by 50%, the construction period reduced by 2/3, and the investment saved by more than 20%.

By virtue of its core advantages of compactness, low-carbon and intelligence, BEWG speedgrain technology perfectly fits the concept of assembly, providing full-process and complete solutions of “simple selection, fast construction and simple operation” for the sewage treatment plants. At present, BEWG speedgrain assembled products are mainly suitable for sewage treatment projects with a treatment scale of less than 20,000 tons/day, which can be quickly applied in such scenarios as decentralized sewage, small and medium-sized urban sewage, industrial point source sewage and rural sewage in key areas.

Mao Jianhua, vice president of BEWG, said that BEAOA and BEWG speedgrain have completed the first step of scientific and technological transformation, and realized the transformation from scientific and technological achievements to projects. Next, they will continue to move forward, form standardized products that can be copied and applied on a large scale, and innovate from multiple perspectives in combination with digital capabilities to form a viable product system. He proposed that enterprises should make innovation a visible value in the process of practicing innovation ideas, and provide technicians with a clear development path from innovation to entrepreneurship and a way to realize future value. Meanwhile, BEWG sincerely invites colleagues in the industry to work together to contribute to the industry, industrial development and national ecological civilization construction.

Up to now, BEWG has owned 772 patents, 420 software copyrights, and 10 provincial and ministerial level science and technology awards. In the future, BEWG will drive innovation and lead development based on the new development stage by following the business purpose of “customer-sourced and innovation-oriented”, continuously increase scientific and technological investment, accumulate scientific and technological achievements, promote scientific and technological industrialization, actively practice the new development concept, promote the high-level leap of the industry and promote the sustainable development of the environmental industry while realizing high quality development of itself.

More

-

A Case of BEWG Selected as a Typical One of Universities-enterprises Cooperation in the Integration of Enterprises with Vocational Schools and Universities in 2021 by the Ministry of Education

-

Low-carbon tool is coming! BEWG successfully realizes the first 10,000-ton project application of AOA technology

-

BEWG signs a framework cooperation agreement with Shanxi Gemeng International Energy Group Co., Ltd. (Gemeng International)